Bharath Rubber

Facilities

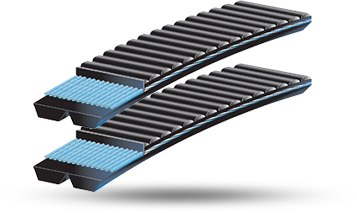

V-Belts WorkShop

Advanced equipment, high technology and products property decided by technology are the premises of market cultivation and realization of the ideal of business creation BHARATH RUBBER (INDIA) LIMITED owns clears and modern factory building, green lands occupy 30% of the company

Conveyor Belt WorkShop

In order to guarantee top-quality products BHARATH RUBBER (INDIA) LIMITED invests a significant proportion of its capital into production equipment to upgrade its Production Technology. The company is equipped with state of the art industry equipped with leading production equipment such as an advanced Mixing Upstream Line Equipment system and utilize computer controlled automatic measurement and blanking, which ensures consistency of rubber material properties , reduces labor intensity, and improves the working environment by its high quality and complete after-sales services.

Bharath Rubber

QUALITY ASSURANCE

& DEVELOPMENT

In-process Quality control, careful choice of raw materials, technological upgradation has ensured complete product reliability and high levels of customer satisfaction. The primordial objective of the R&D departments at BHARATH RUBBER is to produce successful and innovative quality products for our global customers. R&D guarantees products boasting superb performance that are both safe and efficient.

Bharath Rubber R&D departments have specialists who have acquired excellent reputation in the sector over the years. The laboratory and test labs are equip. With the most modern, test facilities. Special equipment enables not only standard investigations but dynamic testing as well.

Our Technology Center employs state-of-the-art techniques, starting from simulation studies using Finite Element Analysis, all the way to validation through rigorous indoor testing. The center has the belt in class testing facilities for Raw Materials, In-Process components and Finished Products Like Industrial and Wrapped Belts, Raw Edge Cogged Belts, Poly-V Belts, Timing Belts and various types of conveyor & transmission.

Quality Control

Various approved testing methods have been conducted to ensure the best quality of our products. This is how we do Quality Control Raw materials and Finished Products.

Cure Characteristic Testers

- Rubber curing time testing.

- Follow JIS K 6301-1975 physical testing method for vulcanized rubber.

Mooney Viscometer

- Mooney viscosity rubber compound testing.

- Follow JIS K 6301-1975 physical testing method for vulcanized rubber.

Tensile Tester

- For Belt Belt tensile strength and elongation ex. poly v-belt raw edge belt, vs-belt.

- Follow JASO E 107, E108 automotive v-belts.

- Follow JASO E 109 automotive v-ribbed belts.

Hardness Tester

Vulcanize rubber hardness testing.Follow JIS K 6301-1975 physical testing method for vulcanized rubber.

Abrasion Tester

- Abrasion resistance testing.

- Follow DIN 53516 determination of abrasion resistance.

Flex Cracking Tester

- Flex cracking resistance testing.

- Follow ISO 132 rubber, vulcanized determination of flex cracking (De Mattia).

Tensometer

- Cord adhesion, tensile strength, elongation.

- Fabric - adhesion. Tensile strength elongation: follow IS 2494 std cotton - based fabric sheet used for belt manufacturing.

- Rubber tensile strength. Elongation: follow JIS K 6301-1975 physical testing method for vulcanized rubber.

reach Us

BHARATH RUBBER (INDIA) LIMITED

55/5 A, Thiruvalavayanallur (Post),

Thanichyam (Via), T.Vadipatti (Taluk),

Madurai - 625 221, Tamilnadu

For Enquiries :

Phone:

0452 -2463772 , 2463773

Customer Care:

094421 16657.

Email:

sales@veeholdbelt.com